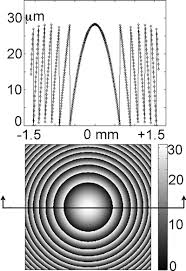

diffractive lens

diffractive intraocular lens

optimized for both

near and far vision

optimized for both

near and far vision

hybrid refractive/diffractive lens

phase function to structure

diffractive lens structure

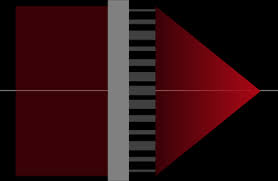

metalens

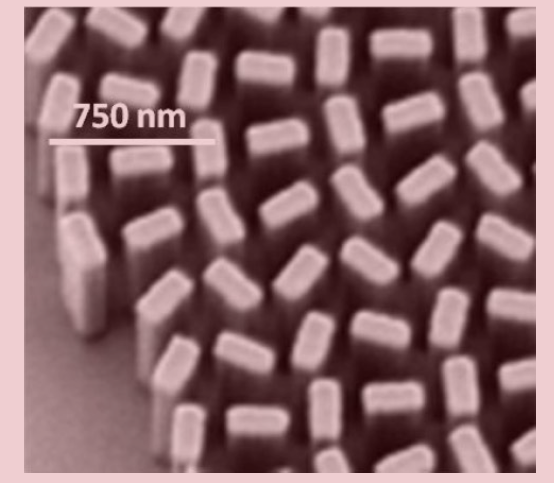

metalens nanofins

symmetrical pillars

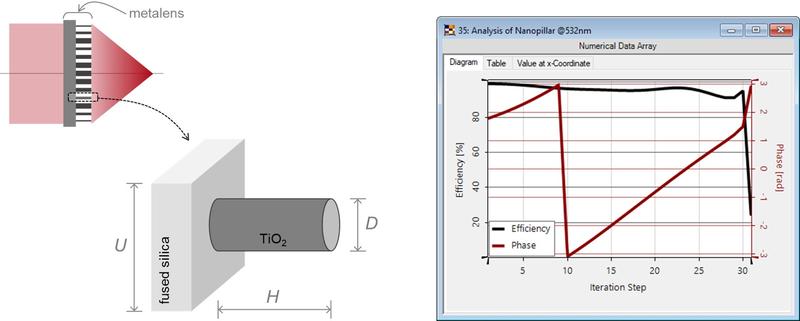

nanopillar 0-to-2pi phase

and transmission efficiency

vs pilllar diameters

for one nanoscale building block

nanopillar 0-to-2pi phase

and transmission efficiency

vs pilllar diameters

for one nanoscale building block

nanofin pillars

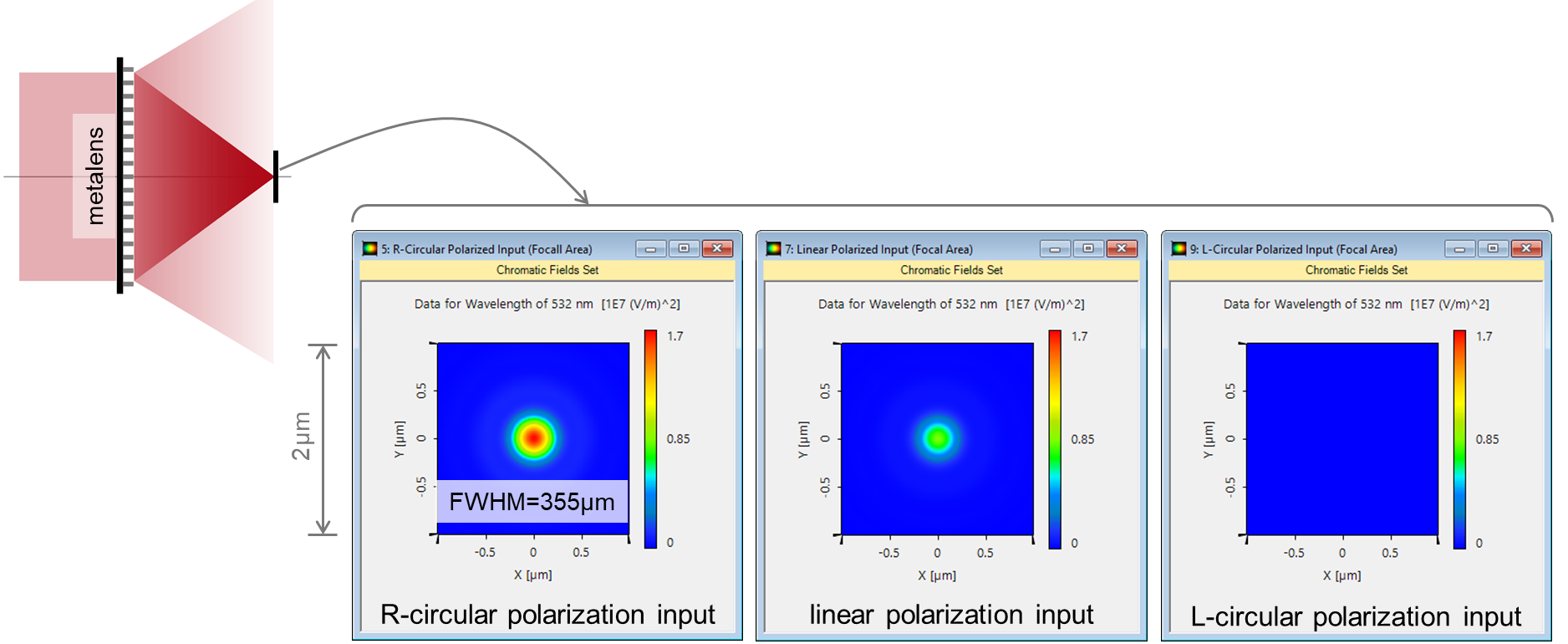

left circular polarization input

linear polarization input

right circular polarization input

left circular polarization input

linear polarization input

right circular polarization input

Diffractive lenses and metalenses

Diffractive Optics Gold Version, and

VirtualLab Fusion Advanced -

includes FMM/RCWA for rigorous local linear grating analysis

VirtualLab Fusion Advanced -

includes FMM/RCWA for rigorous local linear grating analysis

VirtualLab Fusion Diffractive Optics Gold Version includes all the features of Diffractive Optics Silver Version (for beam shaping, and beam splitting), plus modeling of diffractive lenses and metalenses.

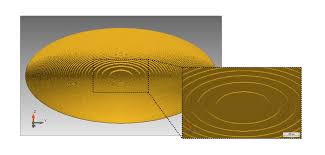

Diffractive Lenses

Diffractive lens physical structures can be continuous or multi-level quantized designs.

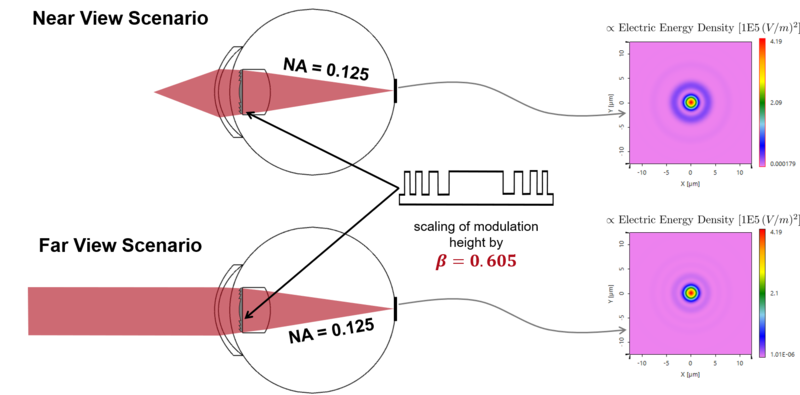

In addition to standard diffractive lens configurations, other practical applications include:

Intraocular diffractive lenses for optimizing both near and far vision and

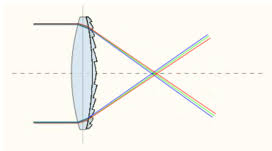

hybrid refractive/diffractive lenses for correcting chromatic aberration

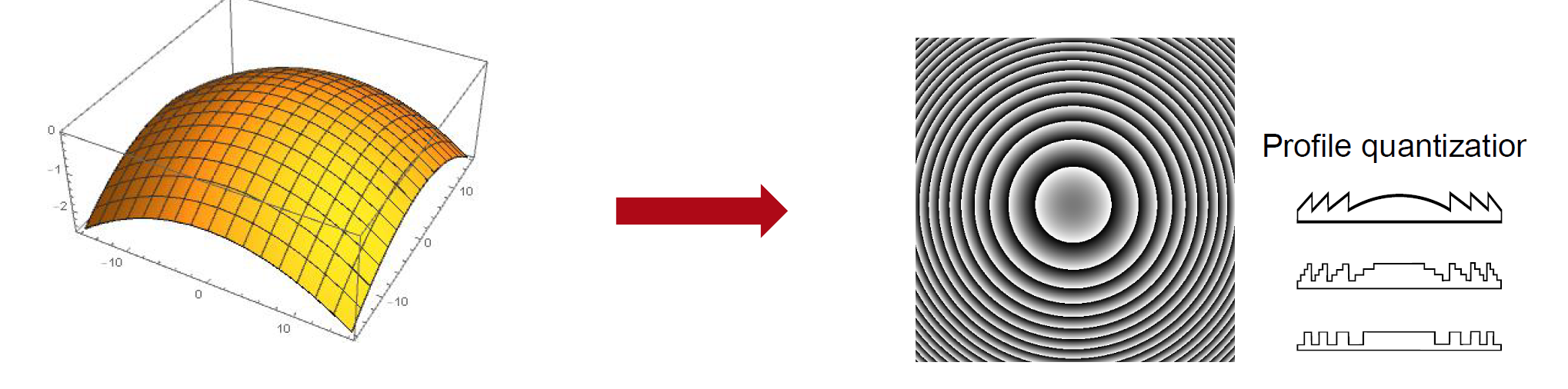

Design of the physical structure starts with a functional design, which can be created in either of two ways.

VirtualLab can import a phase function from Zemax OpticStudio as a wavefront surface response (binary surface) file, or ....

the functional design can be an analytical formula

To create a physical structure for focusing, Thin Element Approximation (TEA) is initially used in regions of the diffractive lens surface closer to the center where the structure has larger feature sizes. As the feature sizes toward the outer regions of the diffractive lens become smaller, the surface is broken into segments, and Local Linear Grating (LLG) is used to rigorously model individual segments. Each segment of the surface is treated as a local grating and is rigorously modeled by the Fourier Modal Method (FMM), also called Rigorous Coupled Wave Analysis (RCWA).

For a technical paper on this topic, click on Local Linear Grating

Metalenses

Features and applications of metalenses

Metalenses can offer advantages over refractive lenses and even conventional diffractive lenses in several applications.

The small form factor, high thermal stability, multi-spectral acquisition, polarization control and even off-axis focusing of metalenses can be advantageous in replacing multiple glass lenses.

Due to the large number of degrees of design freedom, metalenses can also offer advantages over conventional diffractive lenses in focusing, sensing and imaging applications.

Metalenses can simplify abberation correction and chromatic dispersion control.

Nanofin metalenses can be used for polarization-dependent imaging applications. Right and left circular polarization can be focused at different lateral or longitudinal positions.

Wide field of view and high resolution make metalenses helpful for applications, such as: structured light patterns for depth sensing, 3D time of flight, dot pattern generation, and eye tracking for AR/VR applications.

The small form factor and potentially increased light collection and large number of degrees of design freedom make it possible to replace multiple plastic lenses in smart phone cameras.

Attaching metalenses directly to sensors could reduce the size of camera modules.

Also, the semiconductor manufacturing process of metalenses can reduce large scale manufacturing cost.

Automotive applications include outside sensors for LIDAR and driver-assisted safety features, as well as inside sensors for monitoring driver altertiveness and interpreting gestures.

VirtualLab Fusion Diffractive Optics Toolbox - Gold Version

VirtualLab Fusion software offers the Diffractive Optics Toolbox Gold Version for simulating idealized metalenses or designing physical metalens structures.

These structures can be on flat or curved surfaces.

Metalens physical structures can contain either nanofins or rotationally symmetric pillars.

Nanofin structures control phase and polarization by rotating individual nanofins.

Due to birefringence, these nanofin structures are polarization sensitive.

Rotationally symmetric pillar-type metasurfaces are polarization insensitive. Phase and amplitude are controlled by modifying the pillar diameter.

VirtualLab can import the functional design from Zemax OpticStudio as a wavefront surface response (binary surface) file, or ....

the functional design can be an analytical formula.

Metalens surfaces are rigorously modeled by Fourier Modal Method (FMM), which is the same as Rigorous Coupled Wave Analysis (RCWA).

This includes analysis of all diffraction orders.

To create metasurfaces VirtualLab Fusion uses Fourier Modal Method (FMM/RCWA) to rigorouosly calculate nanopillar/nanofin 0-to-2pi phase and transmission vs pillar diameters (see the example on the left).

Quantized nanoscale building blocks are created using the pillars from 0-to-2pi that have high transmission efficiency. These nanoscale building blocks are stored in lookup tables.

The metasurface is then constructed of spatially varying nanostructure building blocks.

Parameter Run

For both diffractive lenses and metalenses, the final structure can be optimized or toleranced by the Parameter Run in the Diffractive Optics Toolbox Gold Version.

Within the Parameter Run, a wide range of physical parameters and merit fuctions can be selected. Minimum and maximum ranges for each parameter can be specified, as well as the number of steps to vary in each range. Parameters can be varied linearly or randomly.

Parameter Runs can be programmed to vary multiple parameters and run simulations automatically using C# or Python.

Analysis results are stored in XML files.

For more information on programming, click on: Programming

The Parameter Run is important for maximizing efficiency and for optimizing high NA applications as well as for tolerancing,

Fabrication Data Files

VirtualLab Diffractive Optics Gold Version can export fabrication data as pixelated or polygon data, and accuracy can be specified.

Several file formats are available: bitmap, text, GDSII or CIF.

The Diffractive Optics Toolbox is used along with VirtualLab Fusion Advanced, which includes the Grating Toolbox (for FMM/RCWA), and Non-Sequential Extension.

The Starter Toolbox can include all the optical elements in a lightpath, in addition to the diffractive lens or metalens, such as: the source, all optical elements, detectors and analyzers. It includes parametric optimization for the entire optical system, to vary distances, positions, sizes, angles, wavelengths, and many more parameters.

VirtualLab Fusion is an integrated software suite of programs for connecting solvers and propagation methods for all the microscale and macroscale components in an optical system.

To contact HMS Technology Sales for more information click here